Preparation Matters

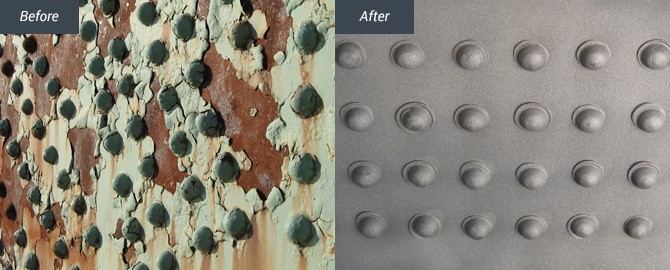

Proper surface preparation extends the life of a coating system. Surfaces can contain many types of contaminants that can negatively affect this life cycle. Oil, grease, chemical salts, rust and mill scale should all be removed prior to coating.

Abrasive Blasting

The most commonly known method of surface preparation is dry grit, abrasive blasting. This is done by projecting small abrasive particles at a high velocity against the surface to be cleaned. This removes rust, mill scale and other surface contaminants. It also creates a profile on the surface, rough enough to provide proper adhesion for a coating. Harrison Muir owns all the necessary equipment needed to provide a safe and efficient project.

Shot-Blasting

Portable centrifugal shot blast machines use centrifugal force to propel abrasive (steel shot) against the surface. The self-contained equipment provides an environmentally friendly dust containment process. The unit recycles the abrasive, removing dust particles and any small abrasive materials, thus reducing the amount of residual waste. Harrison Muir provides shot-blasting for removal of existing floor coating, surface preparation for new coating, blasting for concrete overlays, rite cure removal and preparation for water proofing.

Vacuum Blasting

Vacuum blasting is a process of abrasive blasting and containing dust and other matter within the unit. Where surface preparation requires removal of existing coating, vacuum blasting is an option. Typically this process is used only where environmental containment is not economically viable.

Water Cleaning and Jetting

Water Cleaning and Jetting is a process where water is propelled at a high velocity at a surface. This is done to remove surface contaminants, along with rust and mill scale. The Society for Protective Coatings (SSPC) has standardized the requirements for different levels of cleanliness. Water Cleaning and Jetting eliminates requirement of environmental dust collection, however, containment of water is still necessary.

Dry Ice Blasting

The process of Dry Ice Blasting is a method of cleaning, involving propelling solid carbon dioxide pellets at a surface. The impact of the dry ice pellets hitting the surface of the object delivers more heat to the top layer of dirt, than to the substrate below. This causes the surface contaminants to easily flake off.